WHAT IS VIBRATORY FINISHING MACHINE

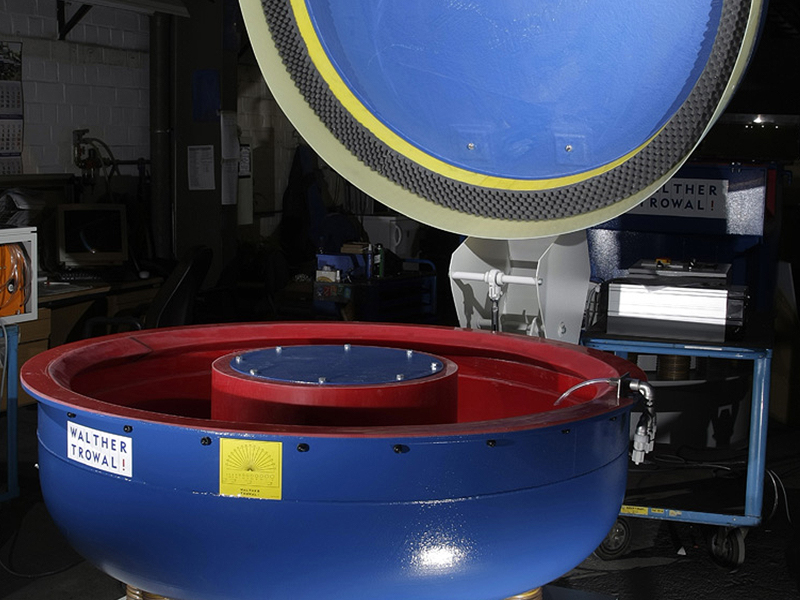

Vibratory finishing machines are usually spring-mounted open-top containers attached to an oscillation or vibration generator. Vibrations are induced by an excenter (a shaft with an offset mass connected to an electric motor).

Parts are placed into the open-top container, which already includes free abrasives (chips) and chemical compounds (or water). Finishing operations occur at vibrational frequencies of 15–50 Hz [Wong19]. The finishing rate can be accelerated by increasing the vibrational frequency. Water may be used instead of chemical compounds to reduce the MRR, which is necessary for achieving a fine surface roughness.

WHAT IS THE VIBRATORY FINISHING PROCESS?

Vibratory finishing is a type of finishing that involves a bowl or tub. This process is unique because it requires you to place a large volume of parts into the bowl and let the parts vibrate inside it. The vibratory function causes friction, making the pieces rub against an abrasive medium until they lose their rough edges and achieve the desired texture.

Vibratory finishing machines are designed to create smooth, consistent finishes for multiple parts and products at a time. They’re useful for cleaning, deburring and polishing products that must meet specific quality standards. Depending on the project, you may choose to use either wet or dry vibratory finishing. The wet process requires the use of water, which can often be treated and recycled for other applications.

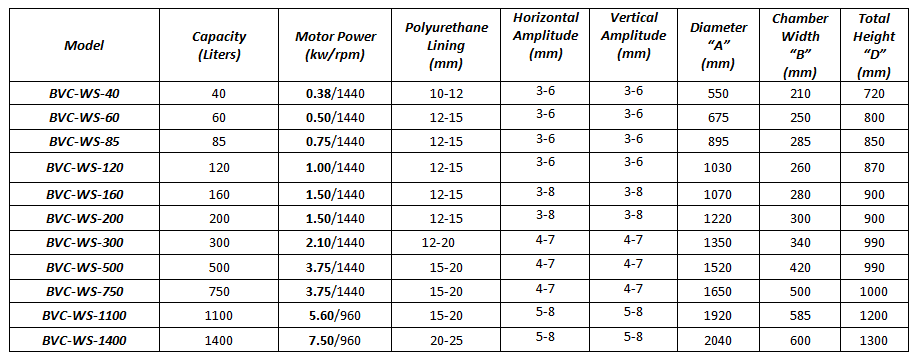

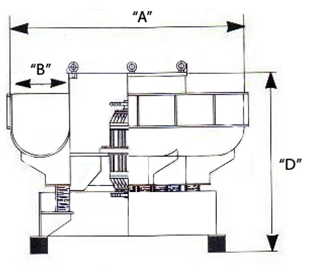

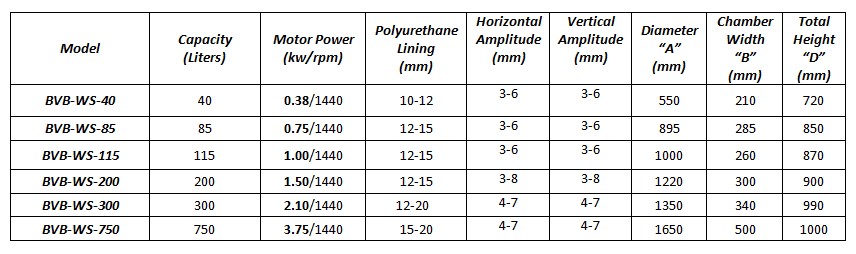

AT-BVC-WS Series Vibrator finishing Machine (STANDARD)

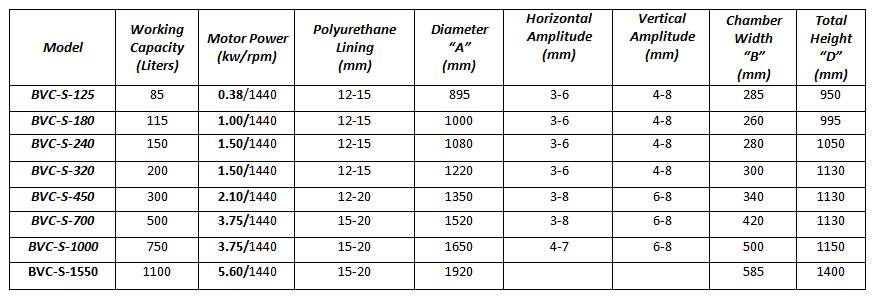

AT-BVC-S Series

Do you need to process large and sensitive workpieces? The AT-BVC-S Series circular vibrators with integrated screening unit offer you a universal solution.

AT-BVB-WS Series

BENEFITS TO VIBRATORY FINISHING

BENEFITS

- Wide Variety of Load Sizes

- Wet or Dry Processing

- Accommodates Small and Large Parts

- Consistent and Efficient Tumbling

- Semi-automated vibratory polishing

- Rolling Action to Protect Fragile Parts

- Short Cycle Times

- Built-In Separating in Some Models

- Continuous Processing; Flow-Through Production

APPLICATIONS

- Heavy and Light Deburring

- Vibratory Polishing

- Burnishing

- Deflashing

- Cleaning and Rust Removal

- Scale Removal

- Drying Parts

- Matt Finishing

- Mirror Polishing

- PrePolishing

- Color Changing